Thesis

The labor landscape in logistics, fulfillment, and manufacturing is undergoing a structural shift. Persistent labor shortages, rising turnover rates, and increasing physical strain on workers have created long-term challenges for industries reliant on repetitive, physically demanding tasks. According to the US Bureau of Labor Statistics, quit rates in transportation and warehousing surged in the aftermath of the COVID-19 pandemic, reflecting heightened labor instability as demand for ecommerce and delivery services accelerated. While quit rates have since returned to pre-pandemic levels amid a tighter labor market with fewer alternative opportunities, the disruption underscored the sector’s ongoing vulnerability to labor shocks and highlighted the urgency of scalable, adaptive automation.

Such automation is becoming increasingly feasible. Conventional automation systems, such as conveyor belts, fixed robotic arms, and autonomous mobile robots, have proven effective in tightly controlled settings. However, they fall short in environments where variability, dynamic movement, and interaction with human co-workers are required. Tasks such as unloading trailers, transferring goods across variable floor layouts, or navigating around human workers continue to rely heavily on manual labor. As these challenges persist, the limitations of rigid automation have created a clear opportunity for mobile, intelligent robotic systems capable of adjusting to the fluid demands of the modern workplace.

Valued at $2.9 billion in 2025, the humanoid robot market is projected to reach $15.3 billion by 2030, growing at a CAGR of 39.2%. This growth reflects increasing confidence in the commercial viability of humanoid systems, supported by technological innovation and widespread investment in AI capabilities. The integration of LLMs and advanced interaction techniques has enabled humanoid robots to perform a wider range of functions across sectors such as manufacturing, healthcare, and education. As development accelerates and costs decline, humanoid robots are emerging as a scalable solution to augment human labor and navigate unstructured, human-centric environments.

Responding to the limitations of traditional automation, Agility Robotics develops bipedal robots that combine human-like mobility with the ability to perform physically intensive tasks. The company is positioned at the intersection of advanced control systems, biomechanics, and practical robotics deployment, offering a solution that aims to bridge the gap between rigid automation and the flexibility required to truly scale automated labor.

Founding Story

Source: Forbes

Agility Robotics was founded in 2015 by Jonathan Hurst (Chief Robot Officer), Damion Shelton (Chairman of the Board), and Mikhail Jones (VP of Software) with a vision to bring human-capable mobility to machines. The company’s origins trace back to Carnegie Mellon University (CMU), where Hurst and Shelton first met as Ph.D. students in robotics. Though their professional paths diverged after CMU, their shared interest in building practical, capable robots for real-world environments would later bring them back together.

After completing his doctorate, Hurst decided to enter academia, joining Oregon State University (OSU) as a professor. There, he helped co-found the Oregon State University Robotics Institute and focused his research on the physics of legged locomotion, examining how animals walk, run, and maintain balance across varied terrain.

Rather than prioritize near-term commercial applications, Hurst aimed to explore a fundamental scientific question: whether the principles of biomechanics could be translated into robotic systems capable of efficient and adaptive movement. That question led to the development of ATRIAS, a research robot built to test theoretical locomotion models. Though the machine resembled a mechanical scaffold more than a humanoid, it successfully demonstrated dynamic walking and running across outdoor terrain. This breakthrough proved that legged robots could be stable, efficient, and adaptable, which are all critical features for navigating human environments.

Meanwhile, Shelton had pursued an entrepreneurial path, co-founding a 3D imaging startup, threeRivers 3D, and successfully exiting the firm in late 2012. Drawing on his experience in bringing advanced technologies to market, he reconnected with Hurst at a time when Hurst’s research was beginning to show practical applications. In 2015, they co-founded Agility Robotics as a formal spinoff from Hurst’s work on legged locomotion at OSU. The company aimed to address the growing need for adaptable automation in warehouse and logistics environments. The founding team also included Mikhail Jones, a graduate student of Hurst’s at OSU and the lead developer of the control software behind ATRIAS. As Hurst said in 2022:

“We believed then that the emerging technologies in legged locomotion would make a viable business opportunity possible at some point in our careers and were aligned from the start that robots should be built for society’s greater good. He [Shelton] pursued an entrepreneurial path while I pursued an academic one and, when the stars aligned in 2015, we founded Agility Robotics along with Mikhail Jones, my star student.”

Over the course of Agility Robotics’ growth, it began to expand its leadership team to support its transition from research-focused development to scaled commercial deployment. The years 2023 and 2024 marked a period of significant transition for the company, as it brought in new executives to strengthen its business, product, and technical operations. Melonee Wise joined as Chief Product Officer (CPO), bringing experience in developing and commercializing robotic systems. Pras Velagapudi was appointed Chief Technology Officer (CTO), taking the lead on technology strategy and innovation in humanoid robotics. Daniel Diez came on board as Chief Business Officer to oversee partnerships and go-to-market strategy, and Jennifer Hunter joined as Chief Financial Officer (CFO) to optimize operational efficiency and drive sustainable growth.

Alongside these key hires, 2024 also saw a change in executive leadership with the appointment of Peggy Johnson as CEO. Johnson, formerly CEO of Magic Leap and a longtime Microsoft executive, was brought in to guide Agility through its next phase of commercialization and scale. Co-founder and outgoing CEO Shelton stepped down from his role in March 2024 to focus on public policy and engagement, drawing on his academic background in the philosophy of science to contribute to broader discussions around robotics, ethics, and the evolving nature of work in a post-AI world.

Product

Source: Agility Robotics

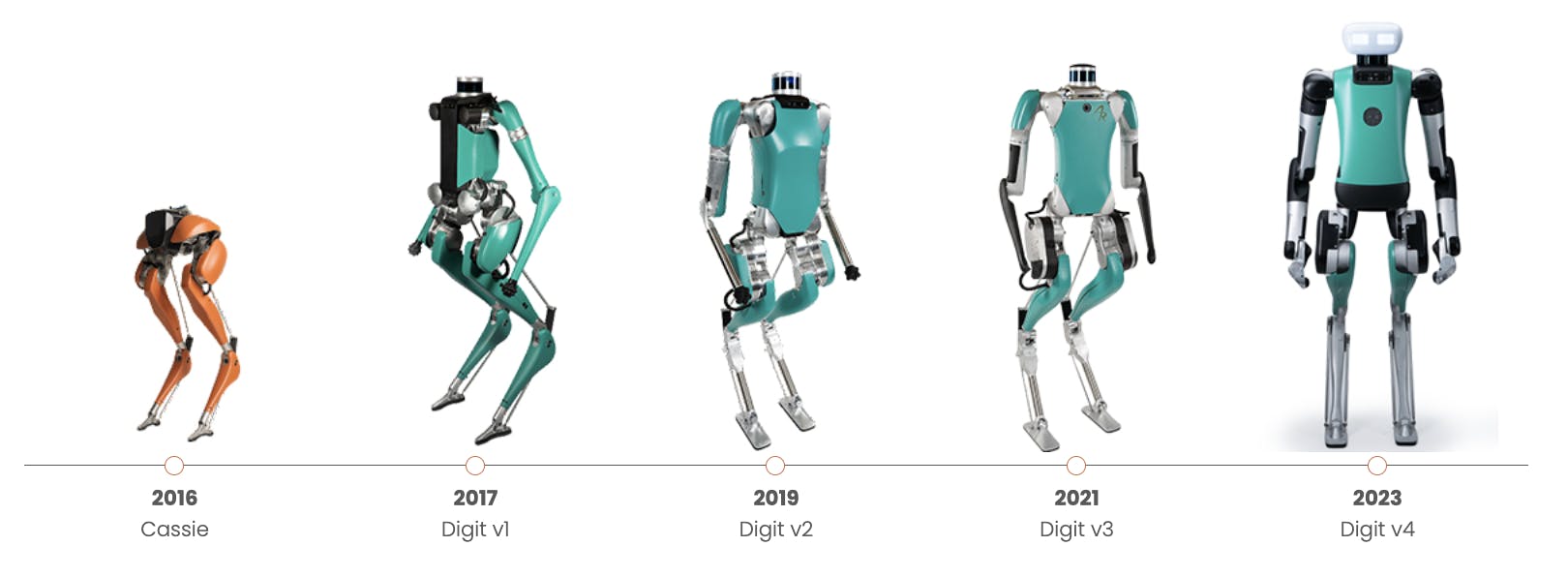

Agility Robotics has continuously evolved its bipedal robot platform since the launch of ostrich-inspired Cassie in 2017. Initially developed as a lower-body research platform, Cassie laid the groundwork for Digit, a more capable humanoid robot introduced in 2019 that added a torso, arms, integrated sensors, and increased computing capacity. Each successive iteration, from Digit v1 to Digit v4 released in 2023, has brought notable improvements, including enhanced mobility, better environmental perception, and increased dexterity. As of March 2025, Agility was preparing to roll out Digit v5 by the end of 2025.

Digit v4

Source: Agility Robotics

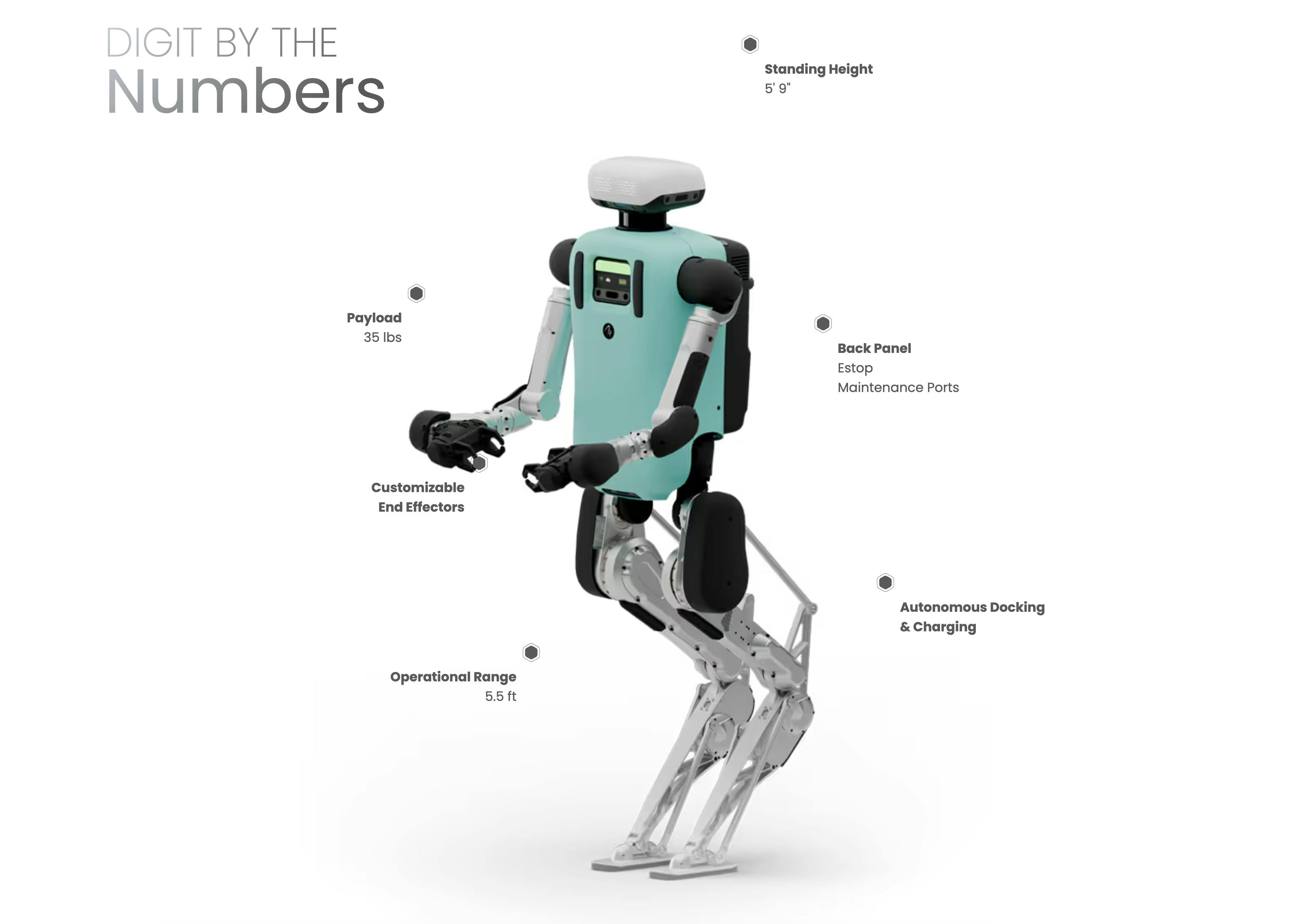

Digit v4 was, as of October 2025, the latest and most commercially focused iteration of Agility Robotics’s bipedal robot platform, purpose-built to perform physically repetitive and labor-intensive tasks in warehouse and logistics environments. Digit stands at a height of 5 feet 9 inches, weighs 140 pounds, and can handle payloads up to 35 pounds. Unveiled at the ProMat 2023 conference in Chicago, Digit v4 introduces a series of design enhancements intended to bridge the gap between advanced robotics research and real-world deployment, with a specific emphasis on human-centric environments.

One of the most visible changes in Digit v4 is the addition of a head-like structure, introduced to enhance human-robot interaction in shared work environments. Although not required for technical functionality, the head serves as a visual anchor that allows human workers to intuitively interpret the robot’s orientation and actions. Earlier versions of Digit relied on a neck-mounted LiDAR (Light Detection and Ranging) sensor, which was effective for navigation but lacked a clear focal point for human observers. The updated design provides a consistent and approachable interface that helps nearby individuals understand whether the robot is engaged in a task, scanning its surroundings, or preparing to move. Additionally, the visual design reflects a broader philosophy of Hurst centered on psychological comfort and ease of workplace integration. The choice of color teal was intentional, as it evokes calmness and avoids the darker industrial tones often associated with dystopian or science fiction imagery.

Since its initial launch in 2023, Digit has undergone a series of technical and mechanical upgrades to strengthen the scalability of its commercial deployment. A notable enhancement is the extension of operational runtime through a more efficient battery system, capable of supporting up to four hours of continuous use. This improvement is complemented by autonomous charging functionality, allowing Digit to self-dock without human intervention. These features reduce downtime and enable more sustained usage across larger fleets.

Digit’s mechanical systems have also been refined to broaden its range of supported tasks. The robot’s limbs now accommodate a wider range of grasping angles, and its upgraded end effectors allow for more flexible object handling. These modifications expand Digit’s capacity to perform workflows. As of October 2025, Digit is capable of loading and unloading totes from a variety of sources and destinations, including Autonomous Mobile Robots (AMRs), flow racks, shelves, unit sorters, carts, goods-to-person systems, and conveyor belts. The system also performs related tasks such as tote stacking, destacking, nesting, palletizing, depalletizing, and recycling, helping to ensure that totes are consistently available where they are needed. Its backward-bending leg design remains a functional strength, supporting stability and maneuverability in confined or cluttered environments.

In parallel with these functional upgrades, Agility has introduced an integrated suite of safety features to align Digit with industrial safety standards. That system incorporates a Category 1 (CAT1) stop system that maintains actuator power during controlled deceleration, helping the robot come to a safe stop without abrupt movements. Additional safety components include a safety-rated programmable logic controller that meets performance level d requirements, manual emergency stop buttons, and the adoption of FailSafe over EtherCAT (FSoE) protocols to ensure secure communication of critical data. These measures reflect Agility’s broader commitment to cooperative safety, allowing humans and robots to operate in proximity without the need for physical barriers. While true collaborative operation is still being developed, these safeguards mark critical progress toward Occupational Safety and Health Administration (OSHA)-compliant deployment.

As Diez explains, Digit v5 will see notable improvements. Its lifting capacity will increase from 35 to 50 pounds, cooperative safety capabilities will be further installed, and more units of Digit will be readily available. The current 2-to-1 ratio for Digit, meaning customers get two units of operating time while another unit is charging, is also expected to be increased to 10-to-1, significantly improving customer ROIs. As of 2025, Digit is the only commercially available humanoid robot and has received several awards, most notably the RBR50 Robot of the Year in both 2023 and 2024.

Agility Arc

Source: Agility Robotics

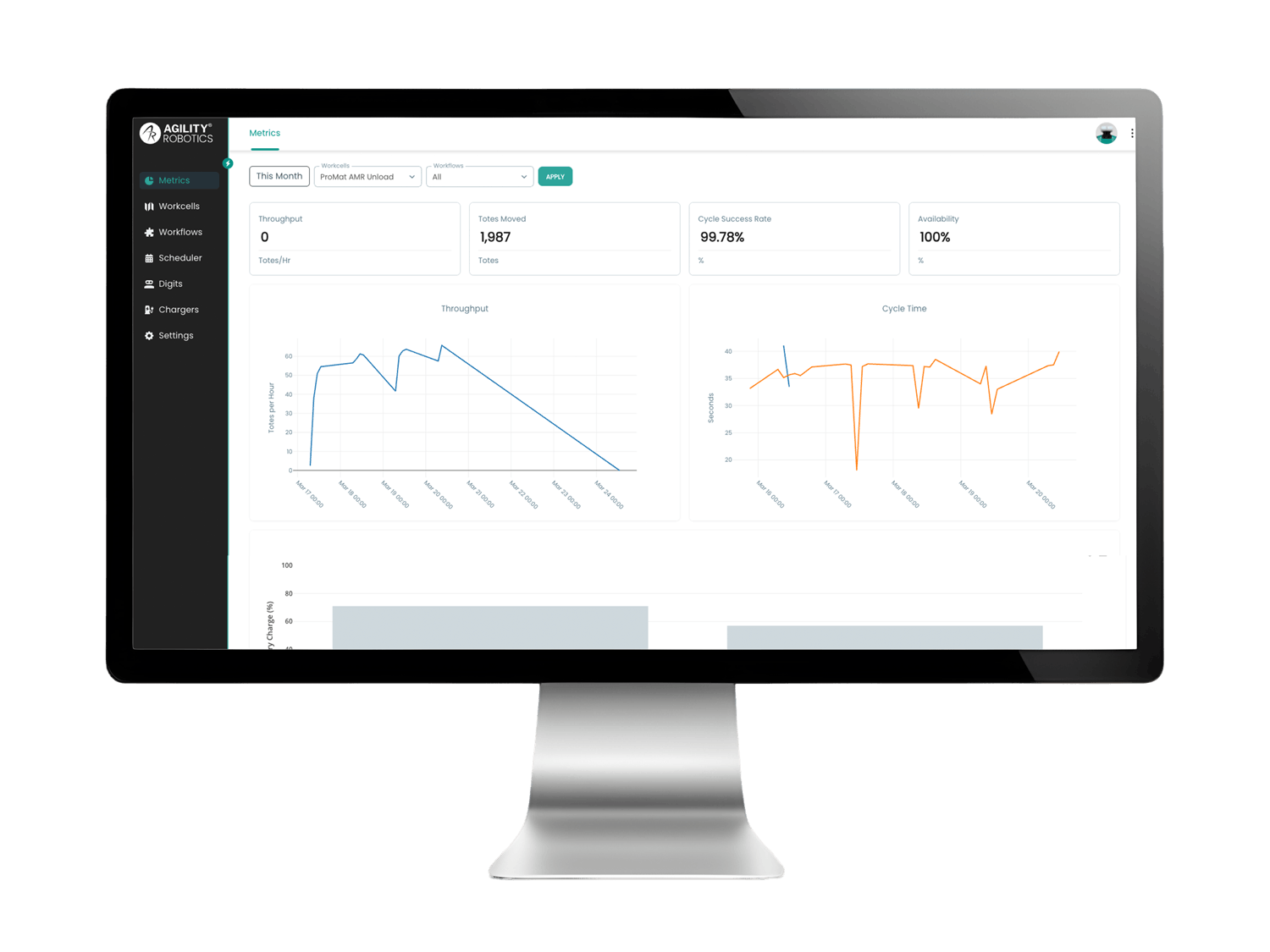

Launched in 2024, Agility Arc is a cloud-based automation platform designed to deploy, manage, and scale fleets of Digit robots within logistics and manufacturing environments. As companies increasingly adopt Digit to address persistent labor shortages and improve operational efficiency, Agility Arc serves as the digital infrastructure that enables rapid deployment and continuous management of these humanoid systems. The platform supports the entire lifecycle of automation deployment, from facility mapping and workflow creation to live fleet monitoring and remote troubleshooting. Developed in collaboration with early adopters through the Agility Engagement Program, Arc reflects direct feedback from real-world deployments and is designed to address the operational complexities of mobile manipulation at scale.

Agility Arc offers visibility into Digit’s performance and system health through an intuitive interface accessible from any location. Operators can view KPIs such as uptime, throughput, mean time between incidents (MTBI), and the real-time status of each Digit and its accessories. The platform enables users to design workcells, configure workflows, assign robots to tasks, and monitor connected devices, including charging stations and emergency systems. These tools allow customers to tailor automation to their specific facility layouts and operational goals, with the flexibility to make adjustments as needs evolve.

A key advantage of Agility Arc lies in its integration capabilities. It supports industry-standard APIs that connect easily with existing warehouse management systems (WMS), warehouse execution systems (WES), manufacturing execution systems (MES), programmable logic controllers (PLC), and autonomous mobile robot platforms. This flexibility allows customers to either integrate Digit into their broader automation ecosystem or deploy it in a standalone mode. For organizations without existing enterprise systems, Arc can function without integration, enabling a faster time to value. As Agility explains, this approach allows customers to deploy Digit within days and begin realizing returns almost immediately.

Delivered through a SaaS model, Agility Arc receives continuous updates that enhance functionality, security, and ease of use. The product’s cloud architecture aims to ensure high levels of security and reliability, giving customers confidence in managing critical workflows across distributed sites. As Wise explained in May 2024, “Our customers will be able to understand what is happening in their workcells and act upon that information, making it easier for them to design, commission, operate, and support their mobile manipulation fleets.”

Market

Customer

Source: Agility Robotics

Agility Robotics began shipping early versions of its Digit robot to customers in 2018, with Ford Motor Company becoming its first major partner. In 2020, Agility and Ford formalized their collaboration to explore how Digit could enhance warehousing and delivery operations. The partnership aimed to “help commercial vehicle customers, including autonomous vehicle businesses, make warehousing and delivery more efficient and affordable for their customers.” Ford received the first two robots off the production line and began testing Digit for integration with autonomous vehicle technology to support last-mile delivery.

As commercial interest in mobile manipulation grew, Agility expanded its customer base across logistics, manufacturing, and industrial supply chains. In 2023, Amazon began testing Digit in its warehouse operations, initially using the robot to assist with tote recycling. Amazon emphasized Digit’s compatibility with human-scale environments, noting that “its size and shape are well suited for buildings that are designed for humans.” That same year, Agility completed a proof-of-concept pilot with GXO Logistics, which led to a multi-year agreement and the deployment of Digit robots at a Spanx facility in Georgia. There, Digit transferred totes from autonomous mobile robots to conveyor belts, marking one of the first commercial applications of a humanoid robot in a warehouse setting.

Source: Colossus Review

Other customers include the Schaeffler Group, which made a minority investment in Agility and committed to deploying Digit across its global plant network. As of 2025, Agility has sold around 100 Digit units, with many already deployed in active workflows.

Market Size

The humanoid robot market is poised for substantial growth, with its global value estimated at $2.9 billion in 2025 and projected to reach $15.3 billion by 2030. This represents a CAGR of 39.2%, making it one of the fastest-growing segments within the broader robotics and automation industry. This potential sharp increase in market value reflects both heightened commercial interest and a maturing technological foundation that is enabling more practical and scalable deployments of humanoid systems.

Morgan Stanley offers a more ambitious outlook, projecting that the global humanoid robotics market could surpass $5 trillion by 2050. This estimate includes not only direct hardware sales but also the broader ecosystem of support infrastructure, such as supply chains, repair services, and maintenance networks. According to the firm’s research, the number of humanoid robots in use could reach over 1 billion globally by mid-century, with 90% deployed in industrial and commercial applications. This growth is expected to accelerate in the late 2030s as technological improvements converge with increased regulatory support and falling unit costs.

Competition

Source: ARK Investment Management

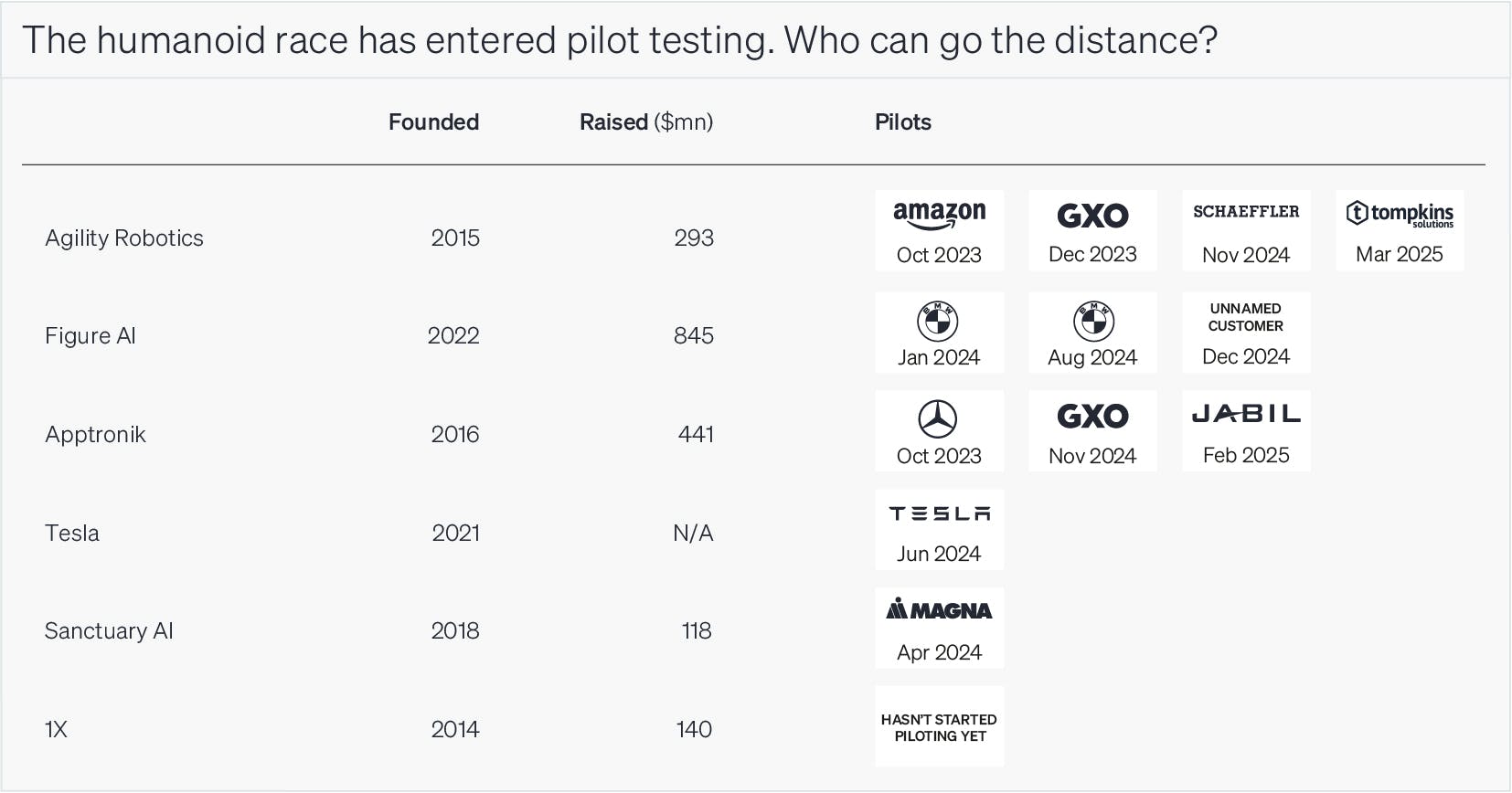

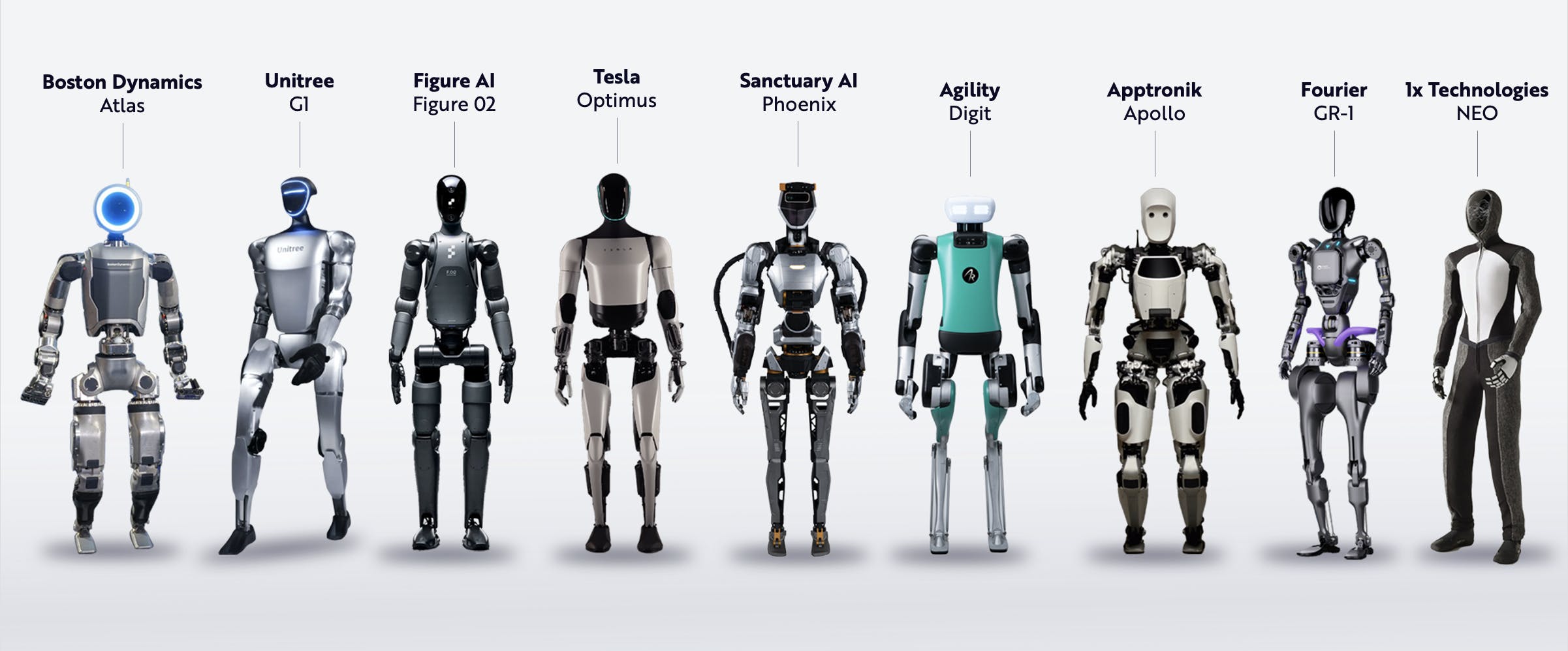

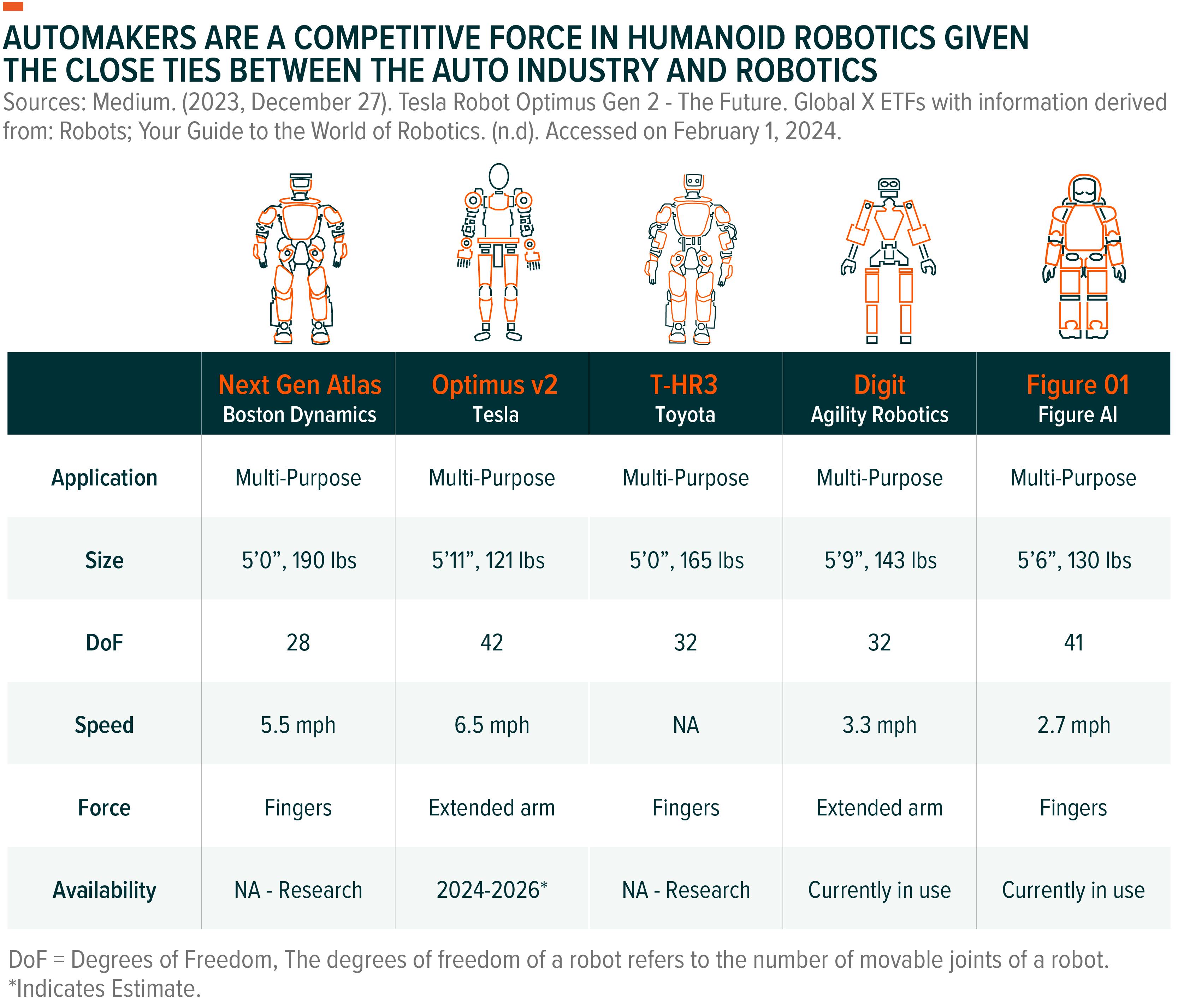

Agility Robotics operates in a rapidly evolving and increasingly competitive landscape of humanoid robotics, where several companies are working to commercialize bipedal robots for dynamic, human-centric environments. Its primary competitors include Figure AI, Boston Dynamics, and Apptronik, among others (Fourier, Sanctuary AI, Tesla, Unitree Robotics). Each of these companies is building humanoid platforms intended to support a variety of applications such as warehouse automation, material handling, and collaborative operations within logistics and manufacturing settings.

Source: Global X ETFs

Although these companies share a common goal of creating general-purpose robots for industrial use, they differ in key areas such as product maturity, design philosophy, and go-to-market strategies. Some focus on highly dexterous manipulation and AI capabilities, while others emphasize rapid deployment, user-friendly integration, and hardware scalability. Their approaches to commercialization also vary. Certain companies are entering the market through early-stage pilots and enterprise partnerships, while others remain in the development phase, refining prototypes and testing performance.

Figure

Figure was founded in 2022 by Brett Adcock, who previously co-founded Archer Aviation and Vettery. In February 2024, two years after it was founded, Figure raised a $675 million Series B round at a valuation of $2.6 billion, with key investors including Microsoft, OpenAI, NVIDIA, Bezos Expeditions, and Intel Capital. In September 2025, the company raised an additional $1 billion led by Parkway Venture Capital at a valuation of $39 billion. As of October 2025, the company has raised a total of $1.9 billion.

Figure introduced its first prototype, Figure 01, in March 2023. Figure 01 was designed to operate in unstructured environments using a vision-language model for real-time task execution. In August 2024, the company unveiled Figure 02, which featured onboard CPU/GPU processing, fully integrated wiring, a 2.25 kWh battery, and a six-camera vision system. The model incorporated a fourth-generation hand with 16 degrees of freedom and demonstrated enhanced autonomous manipulation during pilot deployments at BMW’s Spartanburg manufacturing facility.

In early 2025, Figure launched Helix, its proprietary vision-language-action model built on a dual-system architecture, enabling memory-based task execution and real-time coordination between robots. That same month, Figure announced the launch of BotQ, its high-volume production line capable of manufacturing up to 12K humanoid robots annually.

While both Figure and Agility Robotics aim to address labor shortages through general-purpose humanoid robots, their approaches diverge. Figure is prioritizing long-term autonomy, multi-environment adaptability, and household applications, whereas Agility has concentrated on near-term commercial deployment through its Digit platform, software integration via Agility Arc, and partnerships with logistics providers such as Amazon and GXO.

Boston Dynamics

Boston Dynamics, founded in 1992, is a robotics company that develops both humanoid and non-humanoid robots for use in manufacturing, construction, logistics, defense, and other sectors. The company originated from research at MIT and Carnegie Mellon and initially operated as an independent entity before being acquired by Google in 2013, SoftBank in 2017, and Hyundai in 2020, which purchased a controlling stake for $880 million.

Boston Dynamics’s humanoid robot, Atlas, was originally developed under DARPA funding as a hydraulically powered platform for research applications. In April 2024, the company introduced a new fully electric version of Atlas designed to address labor shortages in industries involving dirty, dangerous, or demanding tasks. The new Atlas emphasizes performance beyond human capabilities and is currently being piloted in Hyundai’s manufacturing facilities following a formal collaboration agreement.

While Atlas remains in a testing phase as of October 2025, Boston Dynamics has achieved commercial deployments with its non-humanoid robots, including Stretch, for case handling in warehouses and Spot for inspection tasks in industrial environments. Compared to Agility Robotics, which is focused solely on bipedal robots for warehouse applications, Boston Dynamics maintains a broader product portfolio with varying use cases and deployment maturity.

Apptronik

Founded in 2016 as a spin-off from the University of Texas at Austin’s Human-Centered Robotics Lab, Apptronik began by developing humanoid systems through research partnerships with NASA. These early efforts included the Valkyrie 1 and Valkyrie 2 robots, which laid the groundwork for the company’s commercial offering, Apollo. Over time, the company has transitioned from academic research to industrial application, with a focus on building general-purpose humanoid robots for warehouse and manufacturing environments.

Apollo, the company’s flagship robot, stands 1.7 meters tall, weighs 160 pounds, and features a four-hour battery life with a payload capacity of 55 pounds. Its modular design enables mounting on legs, wheels, or stationary bases. Apollo incorporates advanced actuation systems, force-control safety mechanisms, and an intuitive LED interface to support collaborative work in human-centric environments. The robot builds on previous platforms developed by the team, including upper-body systems like Astra and bipedal prototypes such as Draco.

Apptronik has pursued strategic partnerships to support deployment and scale. In March 2024, it signed a collaboration agreement with Mercedes-Benz to test Apollo in automotive manufacturing facilities across Europe. Additional pilots have been launched with logistics and supply chain partners, including GXO Logistics and Jabil. In December 2024, the company also partnered with Google DeepMind to enhance Apollo’s AI capabilities. These partnerships are part of a broader commercialization effort backed by over $436 million in funding from investors such as B Capital, Capital Factory, Mercedes-Benz, Japan Post Capital, and ARK Invest. The company’s Series A round in early 2025 reportedly valued it at approximately $1.5 billion.

Compared to Agility Robotics, which has prioritized task-specific deployment of its Digit robot in warehouse workflows, Apptronik is taking a more generalized approach. Apollo is designed to operate across a wide range of use cases, from industrial settings to eventual household applications. While both companies target logistics and manufacturing as entry markets, Apptronik emphasizes modularity, multi-purpose functionality, and integrated safety to support future expansion into new verticals.

Business Model

Source: Agility Robotics

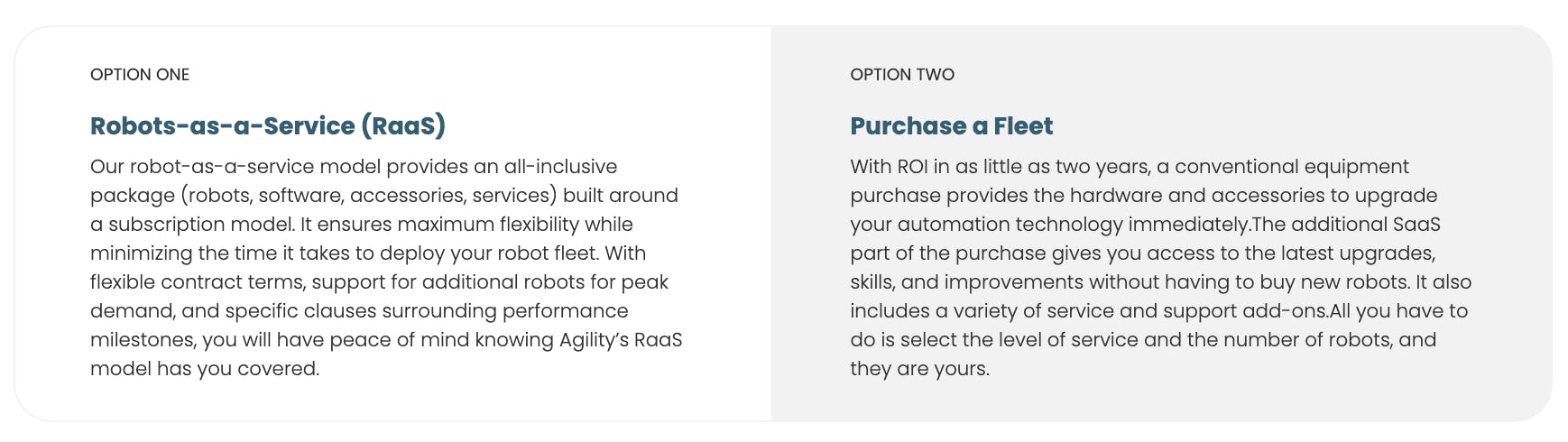

Agility Robotics operates under a dual business model, offering both capital expenditure (CapEx) and Robots-as-a-Service (RaaS) options to meet the varying financial preferences and operational needs of enterprise customers. While the company initially launched with a traditional CapEx model by selling the Digit humanoid robot and charging an ongoing software subscription for access to its Arc cloud platform, Agility has increasingly shifted toward a RaaS model, which has emerged as its dominant go-to-market strategy.

Under the RaaS framework, customers pay a recurring monthly fee that includes the Digit hardware, its dedicated work cell, and all associated software for fleet orchestration and task execution. This model reduces upfront costs for customers and facilitates easier adoption, especially among mid-market logistics providers, retail distributors, and manufacturing firms. Agility retains ownership of the robot, handles maintenance, and ensures continuous performance improvements through over-the-air software updates. The company estimates that customers can achieve a return on investment in under two years, benchmarked against a human worker earning a fully loaded rate of $30 per hour.

To meet rising demand, Agility has invested in internal manufacturing capabilities through its RoboFab factory in Oregon, targeting a production capacity of over 10K units annually. This vertically integrated approach supports scalability and economies of scale while maintaining product quality and safety compliance, which are critical for enterprise-grade robotics deployment. Overall, Agility’s business model is structured to prioritize recurring revenue, scalable deployment, and capital-efficient growth.

Traction

Source: Agility Robotics

Agility Robotics completed construction of RoboFab, a 70K square foot manufacturing facility located in Salem, Oregon, in 2023. Recognized as the first factory purpose-built for mass-producing humanoid robots, RoboFab began initial output later that year. It was designed to produce hundreds of units during its first year of operation and scale up to more than 10K annually. When fully operational, the site is expected to employ over 500 workers. Located approximately 30 miles from Agility’s engineering center, the facility enables close coordination between design and manufacturing teams to support quality control and iterative development.

To demonstrate manufacturing readiness and operational performance, the company hosted a 26-hour continuous demo at the MODEX logistics trade show in early 2024. The live demonstration was structured to replicate shift-based warehouse workflows and highlighted system reliability and task continuity. This initiative followed the launch of the Agility Partner Program, which provided select customers early access to production units in advance of full commercial rollout.

Agility’s strategic partnerships continued to expand throughout 2024. In May, Agility began collaborating with Zion Solutions, a systems integrator focused on logistics and supply chain environments. The partnership aims to support full-cycle deployment by combining Agility’s systems with Zion’s integration expertise and client relationships. Additional operational support was established through a September 2024 partnership with Ricoh USA, which now assists with installation, service coordination, and customer support infrastructure across North America.

Source: Agility Robotics

Agility also expanded its collaboration with NVIDIA in 2025 to enhance its simulation, training, and deployment workflows. The company adopted NVIDIA Isaac Sim and Isaac Lab, two robot simulation and learning frameworks, to train and test behaviors in physically based virtual environments. These tools are used to improve behavioral robustness through reinforcement learning, including enhancements in step recovery and stability under physical disturbances.

Agility also integrated NVIDIA’s AI acceleration platform to support real-time perception and onboard decision-making. Early access was granted to NVIDIA Cosmos and the Mega Omniverse Blueprint, which Agility uses to develop digital twins of customer deployment environments. One of the initial applications involves automotive supplier Schaeffler, which provides digitized representations of bins, shelves, and other facility assets to support coordination and task planning prior to physical deployment. The expanded collaboration includes efforts to make simulation-ready Digit models available to ecosystem partners through NVIDIA Omniverse. Joint presentations at the 2025 GTC Conference by leaders from both companies further outlined the roadmap for integrating physical AI into large-scale industrial environments.

Valuation

Agility Robotics had raised approximately $320 million in total funding as of October 2025, including an estimated $400 million Series C funding round in September 2025, which would bring its pre-money valuation to approximately $1.8 billion. Multiple sources have indicated that the new capital would accelerate the mass production of its humanoid robot, Digit. Other investors include DCVC, Playground Global, Amazon’s Industrial Innovation Fund, Sony Innovation Fund, Safar Partners, and the Schaeffler Group. The company has also received public grants, including support from the National Science Foundation shortly after Agility spun out of Oregon State University.

Key Opportunities

Transforming Labor-Intensive Manufacturing through Scalable Automation

Agility Robotics is positioned to address a significant opportunity in US manufacturing by reducing reliance on human labor in physically demanding roles. The manufacturing sector employs nearly 12 million workers who collectively contribute more than 23 billion hours annually, resulting in a payroll exceeding $780 billion. If humanoid robots could operate at higher utilization rates than human workers, the same output could be achieved with approximately half the number of machines. Robots operating 80 hours per week could match the total annual labor contribution of the existing workforce, providing a pathway to substantial cost savings over time.

Digit is built to operate in environments originally designed for humans. This design allows companies to introduce automation without having to restructure existing facilities or workflows. Digit’s ability to walk, navigate, lift, and interact with the built environment makes it especially suitable for tasks such as transporting materials across variable floor layouts or performing routine logistics functions in fulfillment centers.

Source: ARK Investment Management

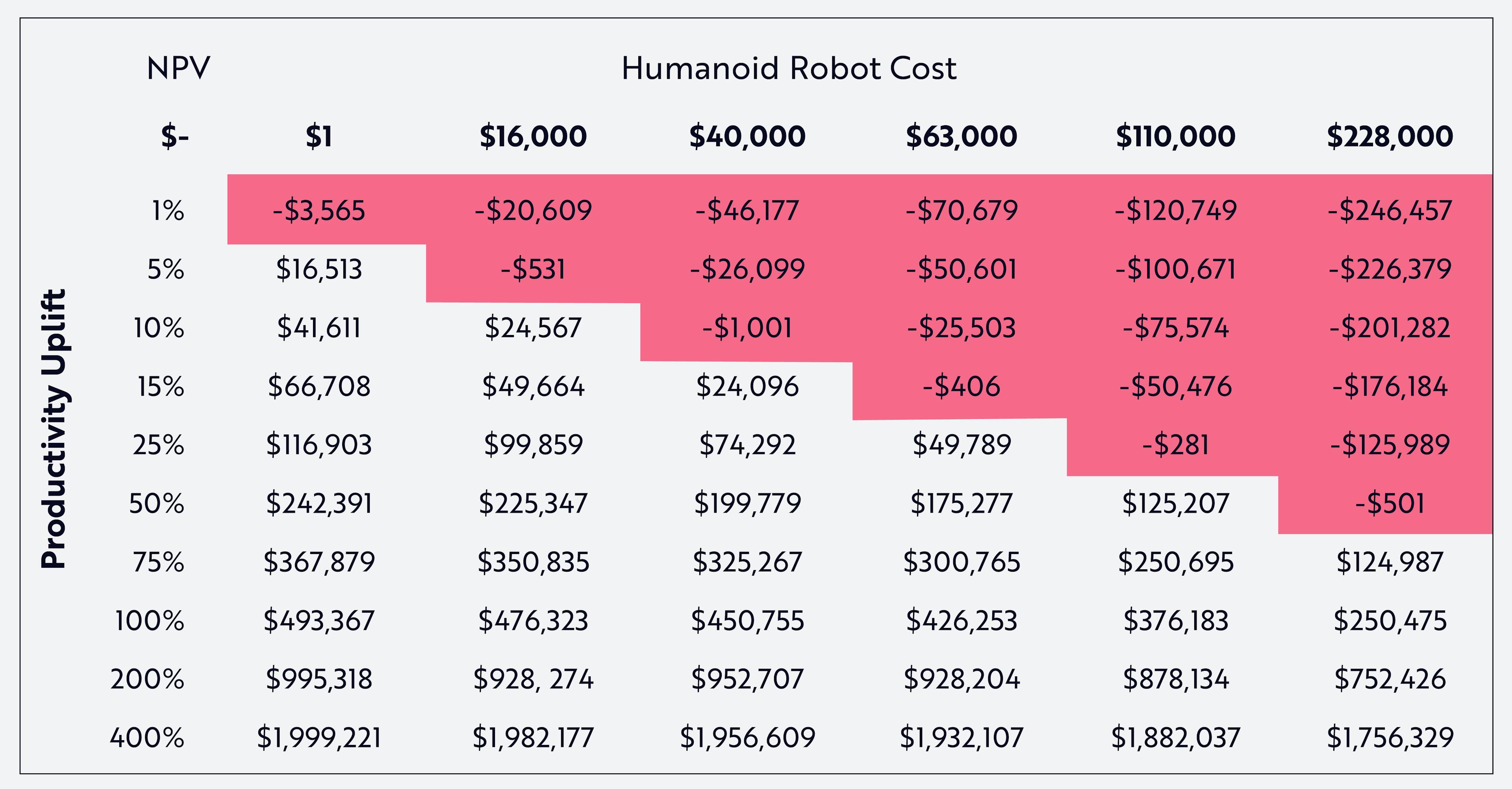

As production costs decline and software capabilities improve, the economics of humanoid robots become increasingly compelling. At certain price points, even modest gains in productivity can justify replacing or supplementing human labor. For example, if Digit enables just a 5-10% increase in productivity relative to a human worker, it could become economically viable in a wide range of use cases. These tipping points are likely to be reached within the next several years, making humanoid robots an attractive alternative to traditional labor for manufacturers facing rising wage pressures and labor shortages.

Unlocking Productivity in Small and Mid-Sized Manufacturing Firms

Source: ARK Investment Management

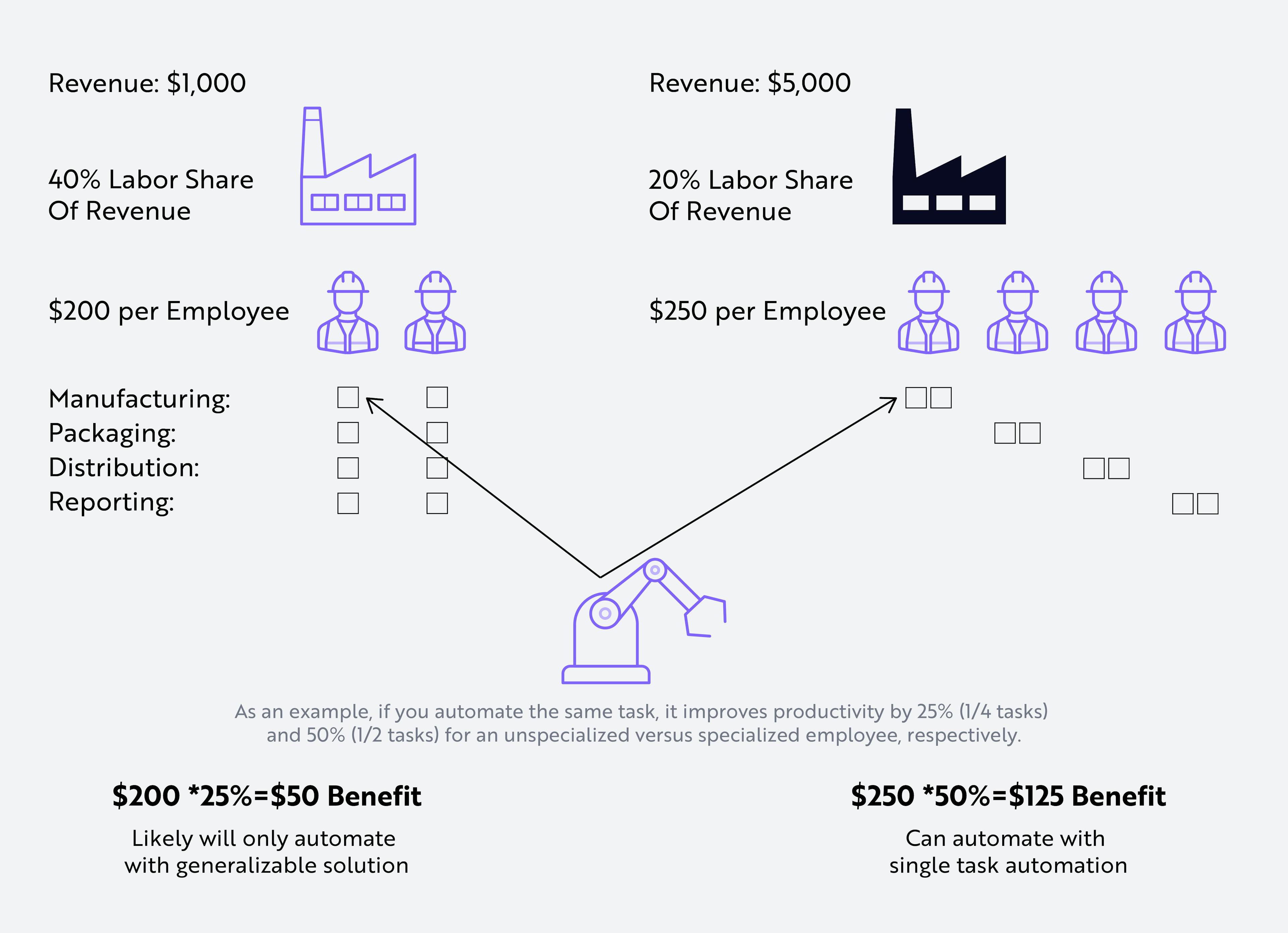

Small and mid-sized manufacturers represent a large portion of the industrial labor force, yet they often face the greatest barriers to adopting automation. Roughly 40% of manufacturing employees work at firms with fewer than 500 workers. These firms tend to rely heavily on generalist labor and often lack the financial and technical resources to implement specialized automation solutions. Unlike larger manufacturers that benefit from task-specific systems, smaller operations require more flexible tools that can adapt to varied workflows.

Agility Robotics can serve this segment by offering a general-purpose humanoid platform that performs a range of tasks with minimal infrastructure changes. In many small facilities, workers are expected to perform multiple roles such as loading materials, organizing supplies, or managing inventory. Digit is capable of navigating between workstations, adjusting to changes in layout, and performing physically repetitive tasks that would otherwise require multiple employees. This makes it well-suited for operations where job functions are not easily separated or standardized.

The financial model for automation in small firms is also different from that of large enterprises. Labor often represents a larger share of revenue, and turnover tends to be higher. These dynamics create a strong incentive to explore automation as a way to stabilize operations and reduce labor-related costs. By providing a flexible solution that reduces both capital intensity and implementation complexity, Agility Robotics enables smaller firms to tap into the benefits of automation that have historically been out of reach.

Accelerating Capability Development Through AI and Semantic Intelligence

Source: Colossus Review

The rapid advancement of artificial intelligence is reshaping how humanoid robots acquire and perform tasks in industrial settings. While Digit remains AI-agnostic, it is designed to integrate with external intelligence systems such as reinforcement learning frameworks and LLMs that enhance its ability to interpret instructions and adapt to unfamiliar environments.

Historically, deploying a robot like Digit in a new facility required extensive manual configuration and task-specific programming. This onboarding process could take several weeks. Today, AI integration has shortened that timeline significantly. When Digit enters a facility, LLMs can help it process task descriptions, navigate spatial layouts, and understand workflows through semantic reasoning. What once required prolonged setup can now be achieved in one to one and a half days.

Reinforcement learning allows Digit to refine its capabilities through simulation before deployment. By practicing in virtual environments, Digit can learn motor skills and decision-making processes that transfer directly to real-world use. This reduces trial-and-error on-site and accelerates ramp-up.

These capabilities enable Digit to take on roles that demand flexibility and contextual awareness, particularly in environments where tasks vary and physical space is unstructured. Over time, as AI systems advance, Digit’s applications could expand into autonomous task planning, exception handling, and human-robot collaboration. Agility Robotics is building a platform capable of evolving alongside these emerging technologies, enabling faster deployment and broader functionality across a range of industrial use cases.

Key Risks

Mounting Cost Pressures & Execution Risk Amid Global Uncertainty

Agility Robotics faces cost pressures as it works to scale the development and deployment of its Digit humanoid robot. The company is simultaneously investing in advanced mobility hardware, AI and perception software, fleet management tools, safety systems, and supporting infrastructure for real-world deployment. These R&D efforts are complex and expensive, particularly given the lack of established standards for humanoid robots and the need to customize integrations for enterprise environments such as warehouses and manufacturing facilities.

In April 2024, Agility conducted layoffs affecting employees outside its core engineering and commercialization functions. This internal restructuring points to the financial strain of operating a capital-intensive model while awaiting broader revenue traction. Even Boston Dynamics, which Hyundai owns and funds, recently had layoffs because its burn rates were simply too high.

Looking ahead, these internal cost pressures may only worsen. The robotics industry is highly dependent on global supply chains, with critical components such as actuators, sensors, microprocessors, and lightweight materials sourced from a wide range of international suppliers. Rising geopolitical tensions and the potential for a global trade war in 2025 introduce serious risks to the stability and affordability of these inputs. Tariff impositions or export restrictions, especially between the United States and China, could drive up production costs and lengthen time-to-value for customers, undermining the economic rationale for adopting humanoid robots at scale.

Regulatory Uncertainty & Safety Compliance Constraints

Regulatory frameworks and safety standards have not yet fully caught up with technological capabilities. Unlike industrial robotic arms or autonomous mobile robots, which benefit from well-established safety certifications and deployment protocols, humanoid robots like Digit exist in a regulatory gray area. As a result, Agility is required to proactively develop and implement custom safety solutions to meet customer requirements and mitigate liability. This includes constructing workcells with safety cages, monitored entrances, emergency stop systems, and perimeter guarding for early deployments.

The lack of uniform standards creates operational complexity and increases deployment friction for customers. Enterprises may be hesitant to fully integrate Digit into core workflows without greater regulatory clarity or third-party certifications that ensure safety and liability protection. Until federal agencies or industry bodies establish formal guidelines for the use of bipedal robots in industrial settings, Agility may be forced to work on a case-by-case basis with each customer to develop acceptable safety solutions, adding time and cost to deployments.

Furthermore, the regulatory landscape is subject to change. If future legislation imposes stricter safety, labor displacement, or liability requirements for humanoid robots, Agility may need to retroactively adapt its products and deployment protocols, which could delay commercial momentum and increase compliance costs. The risk of regulatory lag, combined with evolving public and political scrutiny of robotics in the workplace, presents a material challenge to scaling operations in a predictable and efficient manner.

Summary

Agility Robotics develops humanoid robots designed to perform repetitive, physically demanding tasks in logistics and manufacturing environments. Its core product, Digit, is a bipedal robot capable of working in spaces built for humans, with functionality that includes loading and unloading totes, navigating variable floor layouts, and performing warehouse workflows. The company also offers Agility Arc, a software platform that supports deployment, task assignment, and fleet management.

Recent developments have focused on improving Digit’s technical performance and operational scalability. These include increased payload capacity, extended runtime through autonomous charging, and enhancements in safety systems to support OSHA-compliant deployments. The introduction of Agility Arc has allowed customers to manage Digit robots remotely and integrate them into existing warehouse and manufacturing systems.

Agility operates under both a traditional CapEx model and a RaaS offering, enabling flexible adoption across large enterprises and mid-sized firms. The company has built internal manufacturing capacity through its RoboFab facility and has formed partnerships with organizations such as Amazon, GXO Logistics, and Schaeffler Group to test and deploy its technology in real-world settings.